Collecting-Systems

Chutes

Chutes enable the safe and targeted transfer of injection-moulded parts after demoulding. They are mounted under the mould and/or in the machine bed and guide the parts in a controlled manner onto a conveyor belt, into a container or a hopper. Thanks to their flat design and flexible suspension, they can be adapted to confined spaces and reliably follow the approach path of the mould.

Collecting Chute ARF

Product Description

- Attachment to the clamping plates or in the machine bed

- Direct removal of parts below the tool against the machine direction

- Easy installation thanks to permanent magnets

- Rigid aluminium profile frame

- Movable thanks to chain suspension and follows the tool’s travel path

- Particularly flat and space-saving design

Material Overview

- FM100.001–006

- FM100.010 (PP, antistatic, white)

Fastening Type

- Variant K (chains + screw hook + magnets)

- Variant T (brackets + magnets)

Options

- Laser Engraving

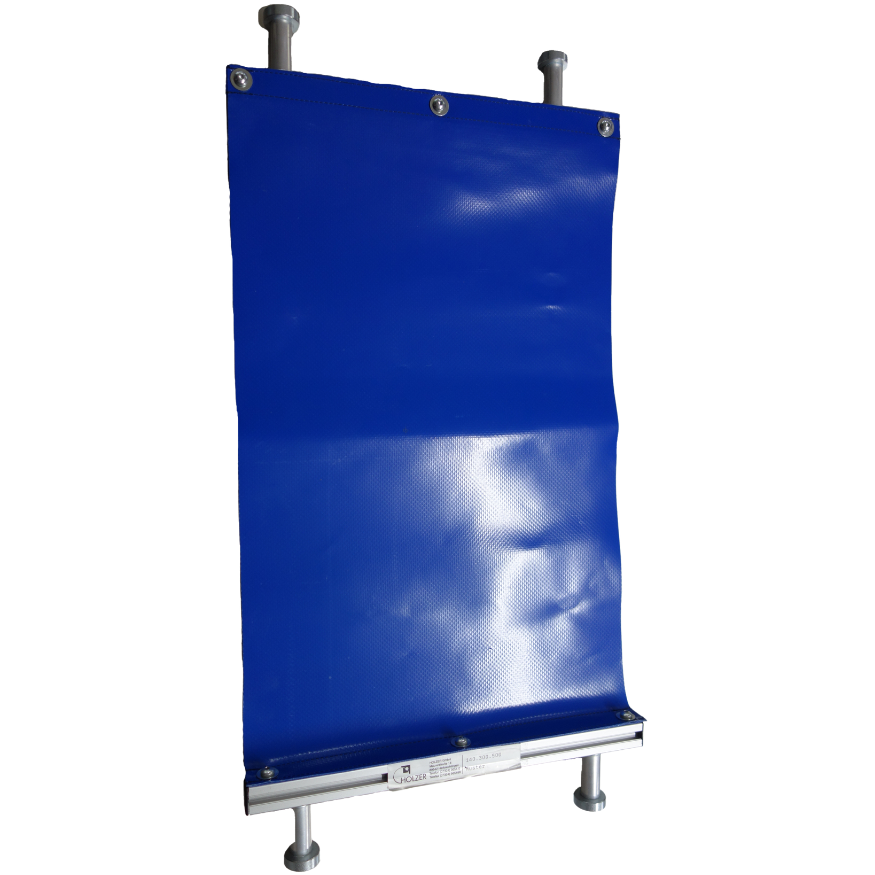

Collecting Chute ARB

Product Description

- Attachment to the clamping plates and the existing sheet metal funnel

- Direct removal of parts below the tool

- Easy installation thanks to permanent magnets

- Aluminium profiles as holders

- Movable and follows the approach path of the tool

- Particularly flat and space-saving design

- Bridging the gap between tool and sheet metal funnel

Material Overview

- FM100.001–006

- FM100.010 (PP, antistatic, white)

Fastening Type

- Variant D (distances + magnets)

- Variant M (magnets)

Options

- Laser Engraving

Arrange your free initial consultation now

Your request is important to us! Don’t hesitate to contact us for personalised advice.

Natascha Hankl

Phone number: +49 7324 9654-54

Email: hankl@holzer-gmbh.com